Every year, Pack Expo provides a stage for groundbreaking technologies that shape the future of packaging. At ProMach, we look forward to unveiling a host of new innovations from across our family of product brands—and this year will be no exception. Among the many exciting launches attendees can expect, one stands out as a first for ProMach product brand Serpa, the introduction of their new DP260 Drop Packer.

The DP260 represents Serpa’s entry into the drop packing segment, expanding their portfolio of end-of-line solutions and reinforcing them as a trusted partner in packaging automation. For customers across industries—from food and personal care to household and chemical products—this development brings fresh opportunities to streamline operations, improve uptime, and reduce costs.

New in Drop Packing Technology

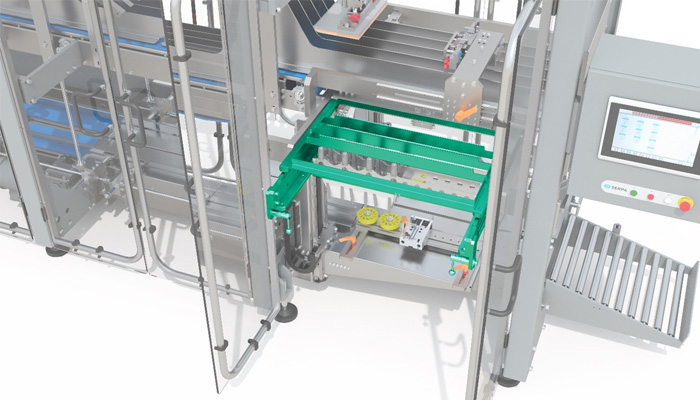

Capable of running up to 60 cases per minute, the DP260 offers both single and tandem drop configurations. Its servo-driven case elevator ensures a gentle product drop, reducing the risk of product damage—an essential feature for manufacturers handling delicate or premium products.

Changeovers, often a pain point for busy production environments, are made rapid and repeatable thanks to a lightweight product grid mounted on a slide-out shelf. This design allows operators to complete full changeovers in minutes without the need for tools, keeping downtime to a minimum and productivity at its peak.

Equally important is the DP260’s robust, simplified build. Engineered to last over 20 years, the machine delivers a low total cost of ownership by minimizing both short- and long-term maintenance requirements. Operators benefit from easy access to all machine components, making upkeep straightforward and ensuring consistent performance. With these combined advantages, Serpa is guaranteeing 98% machine uptime—a significant promise in today’s competitive manufacturing landscape.

Designed for Today’s Markets

Flexibility is at the core of the DP260. The system accommodates products of varying sizes and can arrange them in multiple case-packing formats. This makes it well-suited for a diverse range of markets, including:

- Food and Condiments: Sauces, dressings, and other packaged foods benefit from fast, reliable packing with gentle handling.

- Household Goods: Products such as liquid detergents and disinfectants can be quickly and securely packed to meet growing demand.

- Chemicals and Industrial Products: The machine’s durability and uptime guarantee make it especially valuable in high-output, labor-intensive sectors.

The versatility of the DP260 is perfect for customers seeking an automated solution that integrates with both upstream filling systems and downstream palletizing solutions. It also pairs well with other ProMach technologies, reinforcing the advantage of working with a single-source partner for nearly infinite packaging solutions.

Real-World Impact for Clean Control’s OdoBan Line

The DP260 is already proving its worth on the floor. The first unit, currently showcased at Pack Expo, has been purchased by Clean Control Corporation for use at its Warner Robins, Georgia, facility. The machine will automate the packing of 32-ounce bottles of OdoBan disinfectant spray, a product line that was previously packed entirely by hand.

“Currently, our case packing process for this product is fully manual and labor-intensive, making it one of the hardest jobs at the plant,” explained Nic Bekkers, Technical Manager at Clean Control. “This new machine will enable us to mitigate some of the bottlenecks and pain points we see on the line and increase our productivity by almost double.”

Stories like this highlight how Serpa’s new drop packer goes beyond equipment and delivers real improvements in productivity, safety, and job quality for manufacturing teams.

Serpa’s Expanding Portfolio

For decades, Serpa has been a leader in packaging, known for its cartoners, case packers, and integrated systems. With the DP260, the company adds a drop packer to its lineup, rounding out its ability to handle a variety of customer applications.

“Serpa has been providing customers with a wide range of case packers with different loading types to meet their product needs. Now we’re expanding our portfolio to add a standard drop application to accommodate even more packaging requirements,” said Justin Neece, Serpa’s Vice President and General Manager. “By incorporating our tried-and-true machine design concepts of rapid, consistent changeovers, we’re able to offer customers a new drop packer solution that’s easy to use with speed and flexibility in mind.”

The DP Series also includes a pick-and-place robotic application, offering further options for industries like wine and spirits where precision handling is critical.

See the DP260 at Pack Expo Las Vegas

The launch of Serpa’s DP260 is just one of many exciting innovations ProMach will showcase at this year’s Pack Expo Las Vegas, September 29–October 1. From processing to end of line, ProMach product brands will be presenting a wide array of new technologies designed to improve line efficiency, sustainability, and scalability.

Click here to register for free admission to the show using our promo code 19Y84 and see the DP260 in action at booth W-1148.

With the launch of the DP260, Serpa continues its legacy of engineering excellence while expanding its reach into new markets. It’s a solution that reinforces why so many manufacturers trust ProMach brands to help them protect their reputation, meet consumer demands, and grow their businesses.