When it comes to packaging dressings, sauces, and other condiments and liquid foods, precision matters at every stage, from processing through to the final pallet. In the liquid foods market, manufacturers require production lines that not only safeguard product quality but also keep pace with demand, accommodate diverse packaging needs, and ensure that every bottle leaving the facility meets brand standards.

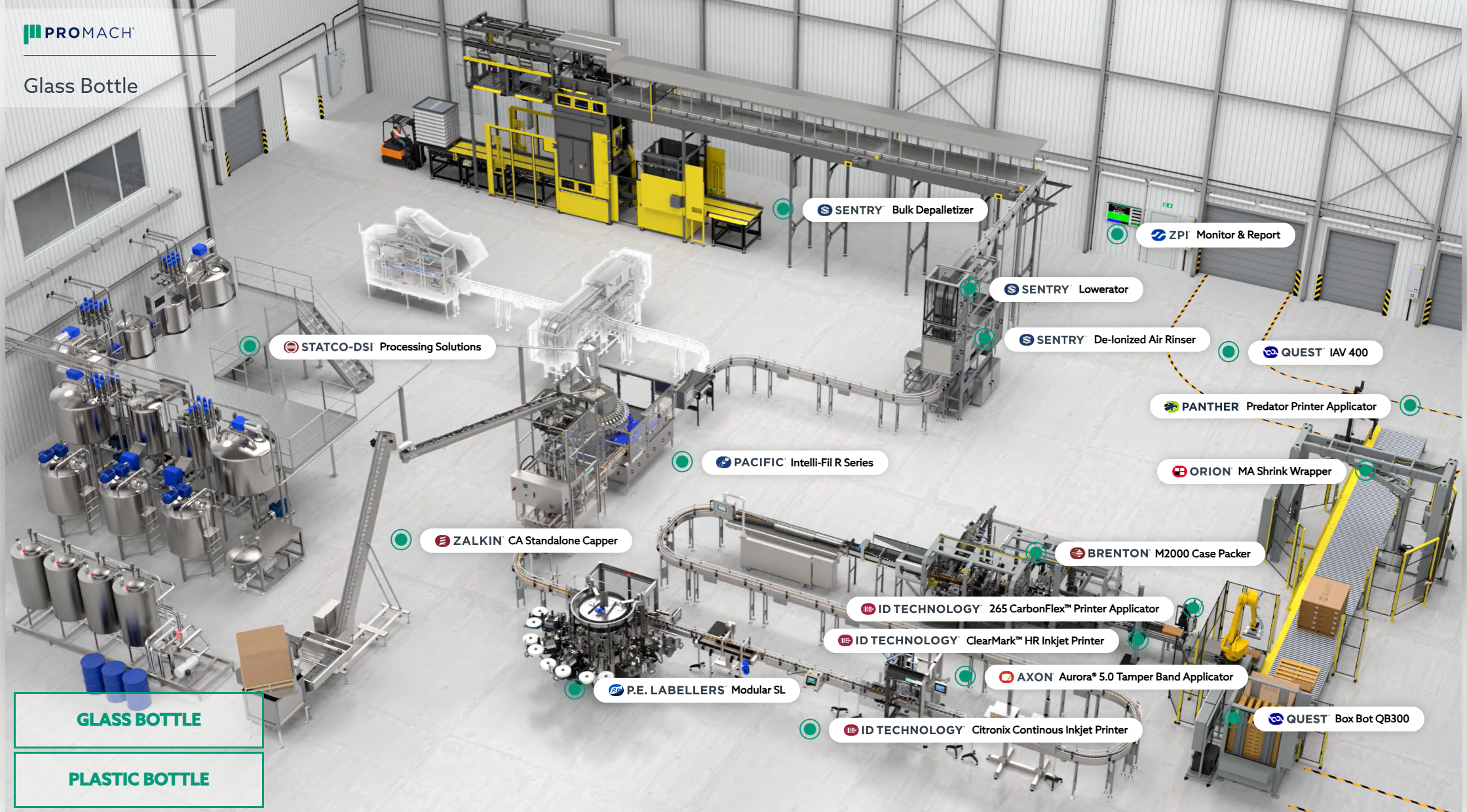

ProMach’s interactive Liquid Foods Solutions animation brings this process to life, showing you two complete line configurations, one for glass bottles and one for plastic, packed with technologies from across our family of product brands. Whether you’re producing in glass for premium shelf appeal or plastic for versatility and durability, you’ll see how ProMach delivers seamless integration from start to finish.

Glass Bottle Line: Preserving Quality

The glass bottle line begins where product quality is born: the Statco-DSI processing area. From here, bulk containers of bottles are handled with care using Sentry bulk depalletizers and Sentry lowerators, ensuring safe and efficient transfer into the filling area.

Pacific fillers provide consistent, accurate filling for even the most challenging product viscosities—perfect for everything from vinaigrettes to thick BBQ sauces. Bottles are sealed with precision using Zalkin cappers, ensuring tamper-proof security and product freshness.

For labeling and decoration, P.E. Labellers delivers high-speed, flexible application that can accommodate wraparound or front-and-back formats, while ID Technology integrates coding and marking for traceability and compliance. Axon tamper band applicators add another layer of safety and consumer confidence before bottles move to the case packing and palletizing stage—where the line is rounded out by more ProMach end-of-line expertise.

Plastic Bottle Line: Speed, Versatility, and Efficiency

On the plastic bottle side, the process starts again in the Statco-DSI processing area, where heat treatment, blending, and CIP systems keep operations efficient and compliant. Bottles are then unscrambled with precision by Pace, orienting each container for downstream operations.

From here, Sentry’s rinser racetrack prepares bottles for filling—an essential step in maintaining hygiene and protecting flavor profiles. Pacific fillers once again handle the filling stage, delivering accurate fills for varying viscosities, followed by Zalkin cappers for secure, consistent closure application.

The plastic line is also supported by labeling and coding from P.E. Labellers and ID Technology, as well as tamper-evident solutions from Axon, ensuring every bottle meets both brand and regulatory requirements. As with the glass line, ProMach’s end-of-line solutions provide fully integrated case packing, palletizing, and wrapping to streamline shipping and distribution.

Integration from Processing to End of Line

What sets ProMach apart in the liquid foods market is our ability to deliver standalone machinery, cellular integrations, and fully integrated solutions as well. Each of the systems shown in the animation is designed to work together, maximizing uptime, reducing changeover times, and enabling manufacturers to scale production without sacrificing quality.

By offering equipment from across our 54+ product brands, ProMach ensures you get the right technology for your product, package, and production goals—all supported by a single, unified partner. Whether your operation demands glass for its premium perception or plastic for its light weight and shatter resistance, ProMach’s expertise covers every step of the journey.

See the Interactive Animations Up Close

Our interactive Liquid Foods Solutions animation allows you to zoom in, explore, and get a close-up look at each piece of equipment in action. You can see the full range of ProMach technologies working together, from processing through to end-of-line, in both glass and plastic bottle formats.

Take a few minutes to explore the lines up close—you’ll get a detailed look at how ProMach’s integrated approach can help you improve efficiency, enhance product quality, and get to market faster.

Click here to explore the glass bottle line.

Click here to explore the plastic bottle line.