When it comes to premium pork, quality extends far beyond the cut. For Perdue Premium Meat Company (PPMC), a subsidiary of Perdue Farms and leader in all-natural, pasture-raised pork, packaging plays a pivotal role in reinforcing their product’s elevated brand promise. That’s why when it came time to scale up production, the Iowa-based operation turned to Ossid—a trusted name in food packaging and weigh price labeling systems—to deliver the speed, precision, and reliability they needed.

As detailed in a new customer spotlight video and testimonial from Ossid, PPMC recently invested in Ossid’s NextGen 2115 Weigh Price Labelers to support the company’s continued growth. The move came after a $29 million expansion to their Sioux Center facility, which added 50,000 square feet of space, new packaging lines, and upgraded processing capabilities.

Watch the full testimonial here.

“We were adding larger packaging machines, and we needed our labelers to hit those higher speeds to match the output we were looking to obtain,” said Jon Schelling, Director of Case Ready Operations & Purchasing, PPMC. That’s when Ossid stepped in.

Ossid, a ProMach product brand headquartered in North Carolina, specializes in weigh price labeling systems, tray overwrapping, thermoforming, vacuum skin packaging, and more. Their machines are widely trusted across the food industry, including within other divisions of Perdue Farms. Known for combining innovative engineering with deep customer collaboration, Ossid approached PPMC’s challenges with one thing in mind: building a long-term solution that could scale.

The recommendation? Two NextGen 2115 Weigh Price Labelers—each capable of labeling up to 150 packages per minute. With WYSIWYG (what-you-see-is-what-you-get) label design software and a modular, stainless steel frame built for harsh protein environments, the equipment checked every box: speed, precision, ease of maintenance, and future scalability.

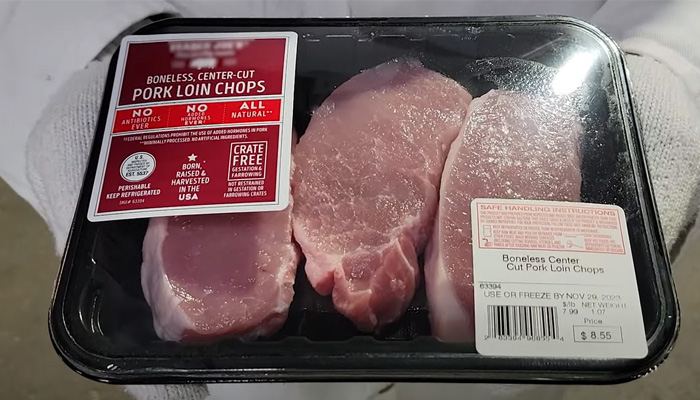

From a production standpoint, the benefits were immediate. PPMC now packages just under 3,000 pounds of pork per hour on its thermoforming line and can run more pounds per day without adding hours to the week. Ossid’s ability to label a wide range of products—from boneless chops to ground pork to complex saddle packs—ensured seamless integration into PPMC’s operations. The open-frame design also improves accessibility for cleaning, a critical advantage in meat processing environments.

“If we’re asking a premium price for our cuts, we need to produce a premium package, and our Ossid weigh price labelers help us do that,” Schelling said. “Our equipment has done everything we were sold on, and the technical support that Ossid offers has been fantastic.”

The testimonial also emphasizes the value of partnership. Ossid’s sales and technical teams worked closely with PPMC to ensure success, not just at install, but as a long-term collaborator.

In the protein industry, performance matters—but so does presentation. PPMC’s story is a testament to how the right technology partner can help growing brands keep up with demand without compromising on quality. Ossid delivered both.

To learn more about Ossid’s weigh price labelers and full portfolio of food packaging solutions, visit www.ossid.com.