The ready-to-drink (RTD) market continues to boom, driven by consumer demand for convenience and variety. From dairy-based beverages and isotonic drinks to sparkling waters, coffees, and functional sodas, brands are racing to deliver products that stand out on shelves and satisfy evolving tastes. But with such diversity comes complexity. Each product type requires unique specifications, processing methods, and packaging solutions. That’s where ProMach’s RTD Solutions come in, offering unmatched flexibility and precision for beverage manufacturers.

Agility at the Core of RTD Production

In today’s fast-paced beverage industry, agility is a necessity. One day, a facility might be producing energy drinks; the next, a functional soda or sparkling water. ProMach enables this level of adaptability through integrated systems that pivot seamlessly between product portfolios without sacrificing accuracy or efficiency. This capability ensures brands can respond quickly to market trends while maintaining the highest standards of quality.

Expertise Across Every Filling Technology

ProMach’s RTD Solutions cover the entire spectrum of filling technologies. Whether it’s hot fill, dairy filling, retort processing, or aseptic filling, ProMach delivers solutions tailored to your product requirements. The company is pushing the boundaries of Extended Shelf Life (ESL) with ultra-clean and aseptic systems designed for high-acid beverages, ensuring safety and freshness from production to consumption.

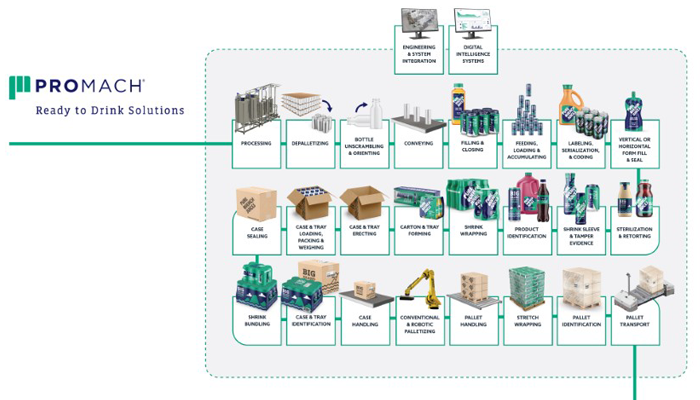

From mixing and blending to end of line, ProMach’s turnkey systems handle every step of the process. This integrated approach allows manufacturers to bring in dairy or non-dairy components, create precise batches, and route them efficiently to fillers, whether for still beverages, carbonated soft drinks, or specialty products.

A Complete Packaging Ecosystem

What sets ProMach apart is its ability to provide end-to-end solutions. The RTD vertical encompasses everything from processing to palletizing, supported by a network of trusted brands:

- Processing: Statco-DSI and TechniBlend

- Batch Retorting: Allpax and Stock

- Conveying: Sentry

- Filling & Capping: MBF, Federal, Fogg, and Zacmi

- Flexible Packaging: Bartelt and Matrix

- Decorative Labeling: P.E. Labellers and Axon

- Labeling and Coding: ID Technology

- Cartoning & Shrink Wrapping: Serpa and Texwrap

- Palletizing & Stretch Wrapping: Sentry and Orion

- Systems Integration: Zarpac and ProMach Integrated Solutions

This comprehensive lineup means customers can choose a turnkey solution or standalone equipment, depending on their needs. The result is a streamlined experience with one point of contact for everything from spare parts to service, simplifying operations and reducing downtime.

Innovation Through Collaboration

ProMach’s success in the RTD space is built on collaboration. Take the example of Westrock, a co-packer with unique requirements for flexibility and integration. ProMach worked closely with Westrock to redesign production lines, creating three identical systems that could rinse, clean, fill, and cap with precision. This unified approach not only optimized startup but also ensured long-term maintainability a testament to ProMach’s commitment to solving complex challenges through partnership.

Why Choose ProMach for RTD Solutions

- Flexibility: Adapt quickly to changing product demands.

- Expertise: Proven capabilities in hot fill, aseptic, ESL, and more.

- Integration: Complete solutions from processing to palletizing.

- Support: Unmatched service and spare parts availability.

ProMach’s RTD Solutions empower beverage brands to stay ahead. Whether you need a filler and labeler, a standalone process system, or a fully integrated line, ProMach delivers the tools and expertise to make it happen.

See it in action in the full video below and discover how ProMach is transforming the RTD packaging landscape in our dedicated market solutions page here: https://www.promachbuilt.com/market-solutions/ready-to-drink-packaging-processing-solutions/