The packaging industry is at a crossroads. Flexible films, those lightweight, versatile materials used in everything from snack bags to personal care packaging, are notoriously difficult to recycle. Recently, major brands like General Mills and Procter & Gamble have stepped up with initiatives to make recycling these materials economically viable. Matt Reynolds of Packaging World recently covered the FlexForward 2025 conference in New Orleans and wrote an article highlighting the panel of sustainability leaders from General Mills and P&G on how brand owners are dealing with packaging recovery (view the article on Pack World here). Programs such as the U.S. Flexible Film Initiative (USFFI) and CalFFlex are designed to subsidize costs for material recovery facilities and invest in technologies that improve the quality of recycled film.

These efforts are promising, but they raise important questions:

- Will financial incentives alone create a sustainable recycling ecosystem?

- How can converters and machinery manufacturers contribute to closing the loop?

- What role should consumers play in driving demand for recycled content?

Why This Matters

Flexible packaging offers undeniable benefits: lightweight design, reduced transportation emissions, and extended shelf life. Yet, its end-of-life challenges have made it a focal point in sustainability discussions. Without robust infrastructure and market demand for post-consumer resin (PCR), recycling flexible films remains a costly endeavor.

Where Our Industry Fits In

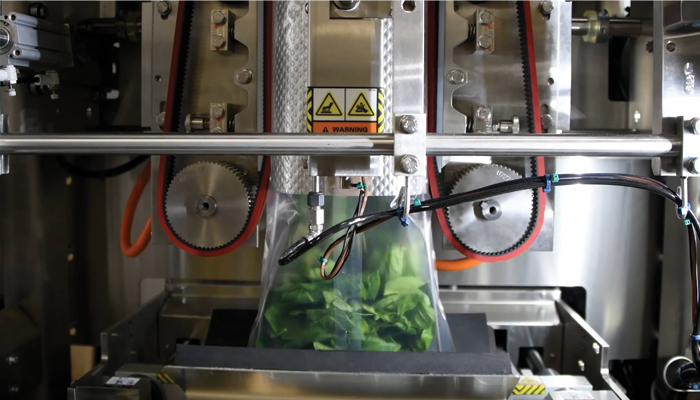

ProMach product brand Matrix designs vertical form-fill-and-seal (VFFS) systems to help brands optimize packaging efficiency. One way machinery can support sustainability goals is by enabling monomaterial packaging formats, films made primarily of polyethylene (PE), which are easier to recycle. By working closely with converters and brands, machinery providers can ensure that packaging designs align with recyclability standards without sacrificing performance.

Similarly, ProMach product brand CL&D Graphics, a leader in custom printed flexible packaging, plays a critical role in design-for-recyclability. Choices in inks, adhesives, and coatings can make or break a package’s ability to be recycled. CL&D’s expertise in creating packaging that meets both branding and sustainability requirements positions converters as key partners in this circular economy.

The Bigger Picture

Technology like P&G’s Flexloop process, which removes contaminants from recycled film, shows that innovation is happening. But technology alone isn’t enough. Collaboration across the value chain, brands, converters, machinery manufacturers, and recyclers, is essential. And let’s not forget consumer education: surveys show that shoppers often value recycled content more than recyclability claims, but they need clear communication to make informed choices.

Questions for You

- How can machinery and packaging design work together to make recycling easier and more cost-effective?

- Should brands prioritize monomaterial packaging even if it limits certain design features?

- What strategies can converters adopt to integrate PCR without compromising quality?

- How do we balance consumer convenience with sustainability goals?

Your Turn: What do you think? Are these initiatives enough to move the needle, or do we need a more radical rethink of flexible packaging? Share your thoughts in the comments—we’d love to hear from you.

Click here to read Matt Reynold’s full Packaging World article highlighting the panel at FlexForward 2025.