Edson, a ProMach product brand, launches automation technology for Knock Down Flat (KDF) Infeed Management System

Automation has become increasingly important for manufacturers in the packaging industry. This is due to a variety of factors such as the demand for increased efficiency, process performance, changes in the labor market, product quality, and safety. This is also true for the tissue industry, where manufacturers are looking for automation on their line for tasks such as case loading, removing straps, squaring them up, and so on.

Edson, a ProMach product brand and leader in case and tray packing solutions specifically designed for the converted paper, diaper, and nonwoven markets, specializes in creating advanced technology that creates ideal solutions for their customer’s end of line operation. Listening to their customer’s needs and keeping an ear to the ground for industry trends, they developed a new technology that addresses customers’ automation concerns while maintaining cleanliness and consistency, another key component for their customers.

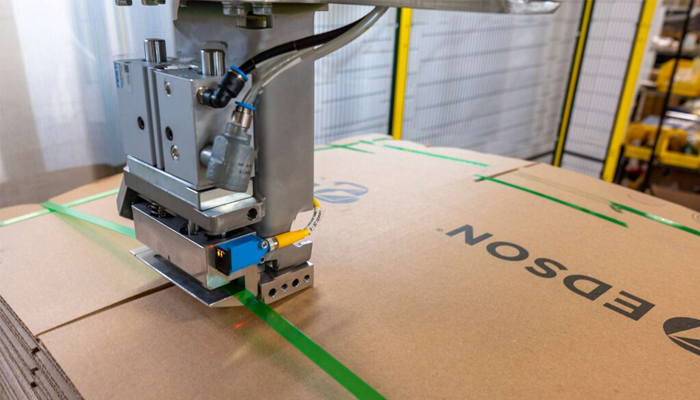

Edson launched the KDF (Knock Down Flat) Infeed Management System which is targeted at any manufacturer currently using Edson or non-Edson case packers that feed KDF stacks into the infeed (it can essentially be integrated with any existing case packer or equipment needing KDF preparation or bands removed). This technology isn’t a first for the packaging industry, but it is a first for the converted paper industry.

In a recent article for Tissue World Magazine, Josh Goulet, Account Manager at Edson writes, “What we’ve found from talking to various people is that the usefulness of this robotic system doesn’t end with tissue and nonwovens – it can be extended to a plethora of applications. We developed the line because we are always thinking of ways to minimise the amount of operator intervention on our equipment. Customer demand was the main driver for development – once customers started to ask, it made it a no-brainer to start thinking about it more seriously and bringing it to life.”

The automation includes preparing a stack of KDFs, scanning and verifying, removing and safely chopping straps, rotating, justifying, stacking, and more before releasing it to the case packer.

Read more about the technology of the KDF in the Tissue World Magazine article below, written by Josh Goulet at Edson. And learn more about Edson on their website here: https://www.edson.com/