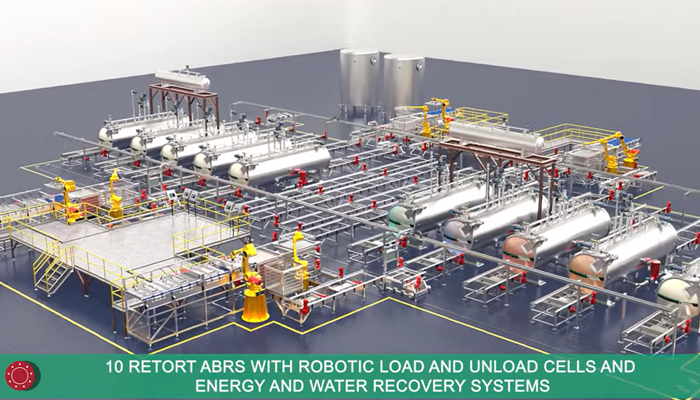

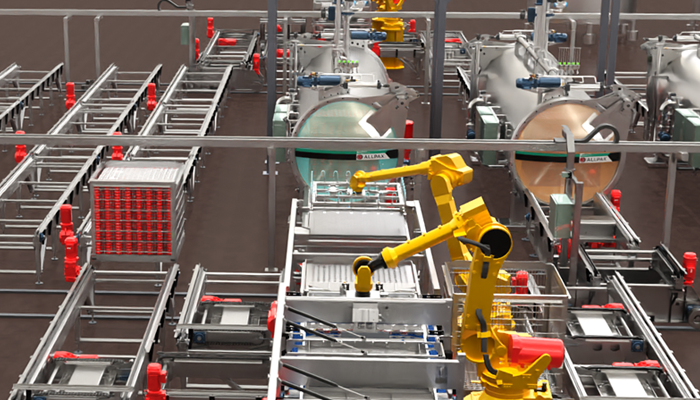

Allpax, a ProMach product brand and global leader in the design and fabrication of food sterilization such as cookers, retorts, autoclaves, and material handling automation equipment, has a new video out highlighting advanced automation with robotics and batch retort systems. The new video features new high-speed sweep style loading/unloading systems for handling cans, up to 2,000 units per minute throughput per loader and unloader cell. At the loading cell, one robot sweeps cans into a basket while another places a slip sheet between the layers. The unloader cell reverses the process by having a robot sweep cans out of the basket while the other robot removes the slip sheet between the layers. And while this video is an animation, it is based on an actual production system that Allpax recently delivered to a customer!

The Importance of Advanced Robotics

Robotic sweep-type loaders provide an alternative for operations looking for greater flexibility in batch retort automation systems. The robotic sweep loading reduces stress on the structure of the loading system, extending the service life. Time and labor are saved because robots can perform automatic changeover between can sizes vs traditional non-robotic loaders. Robots can also be called in when systems are upgraded or decommissioned.

Not just for cans, Allpax also offers robotic automation systems for handling pouches, bowls, cartons, and more. These can run 300 units per minute or more.

Learn more about Allpax on their website here and see the full video below.