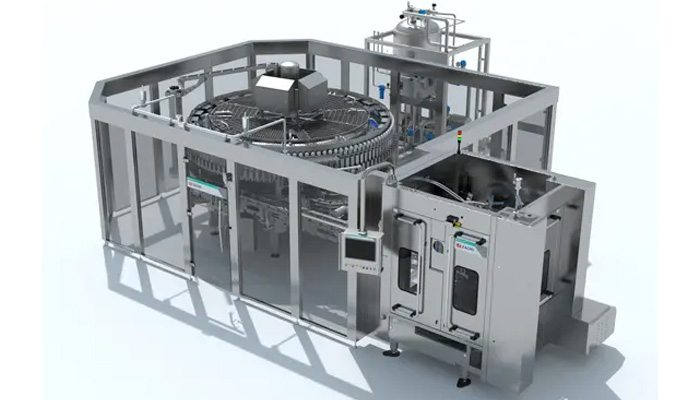

Each year at Pack Expo, ProMach brands showcase breakthrough technologies designed to move the packaging industry forward. With so many exciting new launches planned for this year’s show, we’re spotlighting several standout innovations in advance. One that beverage producers will not want to miss is the Zacmi Be-Fill Rotary Can Filler, a next-generation solution that redefines flexibility, efficiency, and precision in can filling.

A New Standard in Beverage Filling

The Be-Fill filler combines Zacmi’s decades of proven expertise with a forward-looking design that addresses today’s most pressing challenges in beverage packaging. Built for maximum versatility, the Be-Fill can handle a wide variety of beverages, including:

- Beer and carbonated drinks (2°C to 18°C/36–64°F)

- Energy drinks

- Juices and flat products, hot-filled (up to 90°C/194°F) or cold-filled

It accommodates aluminum and metal cans ranging from 80mm to 200mm in height, with the ability to switch quickly between can-end formats (200 to 206) without mechanical adjustments. These rapid format changes dramatically reduce downtime and help manufacturers stay nimble in fast-paced markets.

High Performance in a Smaller Footprint

Be-Fill is scalable from 50 to 128 filling valves and can integrate seamlessly with Zacmi’s seamer options. The model being featured includes a 116-valve carousel with a 12-head seamer—delivering impressive throughput without requiring more floor space.

For beverage producers facing rising demand and constrained production areas, Be-Fill’s ability to deliver increased speeds on the same or smaller footprint is a game-changing advantage.

Precision and Product Integrity

At the heart of Be-Fill’s innovation is its electronic volumetric system, which ensures exact dosing into every can. This level of precision minimizes product waste, improves consistency, and provides peace of mind for quality-focused producers.

The system’s specialized valves are tailored to product type:

- Dual-channel flushing valves reduce oxygen pickup and optimize CO₂ consumption for sensitive, carbonated products.

- Single-channel valves manage standard products with ease.

- Internal recirculation valves provide preheating for hot-filled beverages.

Together, these technologies safeguard product integrity and extend shelf life, while maintaining flexibility across product categories.

Operator-Friendly Design

Beyond speed and accuracy, Be-Fill is designed for ease of maintenance and operator convenience. Key features include:

- Quick-release valves fixed with only two screws for fast assembly and disassembly.

- Reduced lubrication needs thanks to a specially designed lower manifold that optimizes gas and liquid flows.

- External buffer tank feeding that minimizes product accumulation inside the filler.

- Innovative can-ejection system and easily removable hygienic covers for fast cleaning.

Every detail of Be-Fill reflects Zacmi’s commitment to reducing downtime, simplifying upkeep, and extending equipment lifespan.

Expanding Capabilities With Liquid Nitrogen Dosing

For manufacturers requiring stringent standards or extended shelf life, Be-Fill can be equipped with an optional liquid nitrogen dosing system. This feature expands its application range and makes it well-suited for both traditional and emerging beverage categories, from craft beer to functional drinks.

Why Be-Fill Matters

Beverage producers today face increasing pressure to deliver more variety, maintain product quality, and optimize efficiency—all while managing costs and responding quickly to shifting consumer preferences. The Zacmi Be-Fill directly addresses these needs by offering one machine that does the work of many, enabling producers to:

- Transition easily between carbonated, still, hot-fill, and cold-fill products.

- Maintain precision dosing and minimize waste.

- Achieve faster speeds without sacrificing space.

- Simplify changeovers and maintenance, maximizing uptime.

This balance of flexibility, productivity, and reliability positions Be-Fill as a critical asset for manufacturers navigating competitive beverage markets.

Be sure to visit the ProMach Innovation Station at booth W-1500, where Be-Fill and other breakthrough technologies will be highlighted as part of our Innovation Spotlight Series.

To learn more about the Be-Fill and other new technologies, click here to visit the ProMach Innovation page for details.